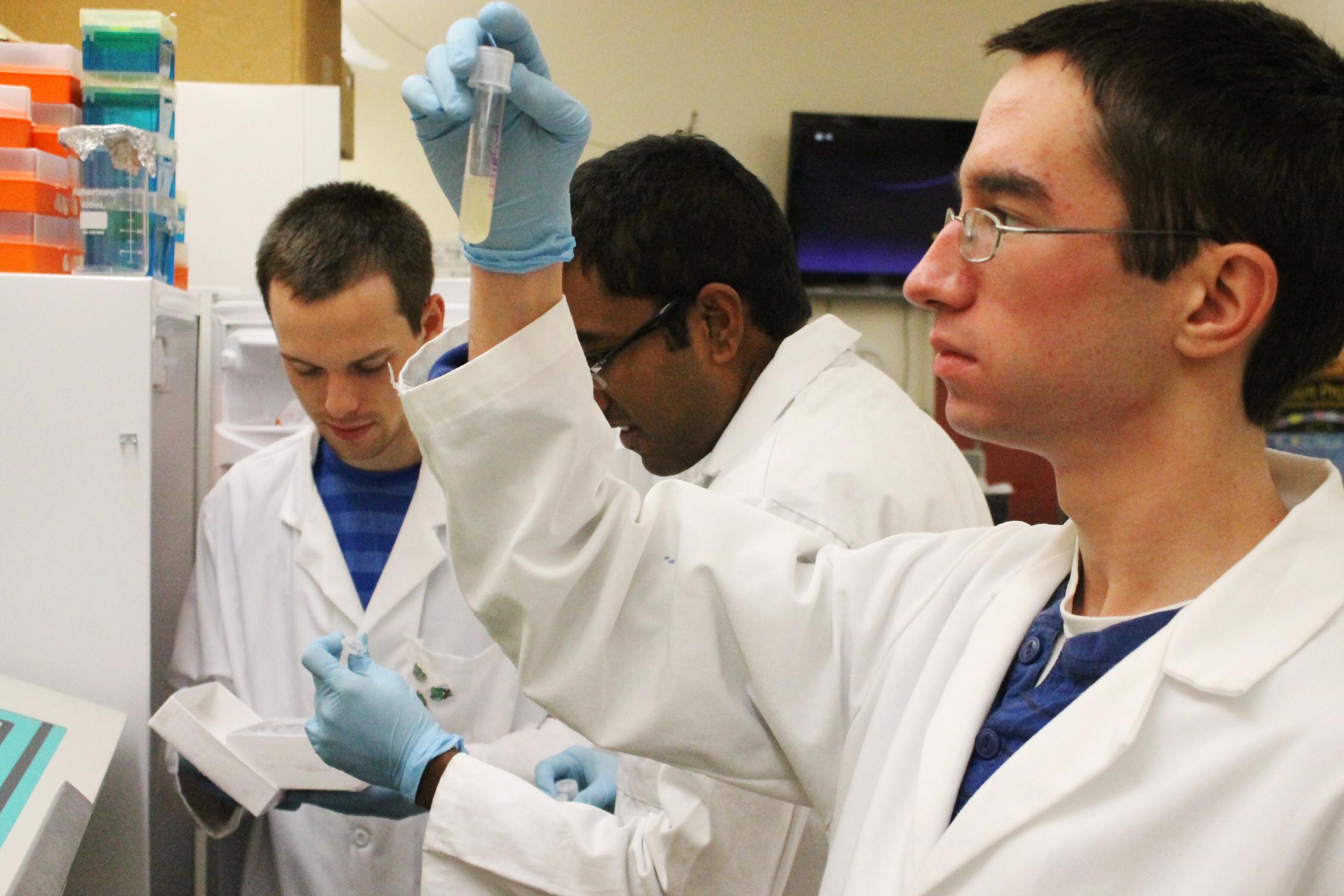

Biological engineering students win first place

A team of biological engineering students took the gold prize at the International Genetically Engineered Machine competition for their project “AMPed up E. Coli.” This is the fifth year in a row USU’s team has won first place.

“I’m very proud of this year’s team,” said Charles Miller, faculty adviser for the team. “They’ve worked very hard and their successes are a testament to their efforts.”

The team’s project this year involved antimicrobial peptides, which are found in every multicellular organism on the planet, according to team member Ryan Putman, a junior in biological engineering.

Putman described how bacteria becomes immune to antibiotics and then scientists have to discover new ones. The idea behind the iGEM project was to generate AMPs, the body’s natural defense system, for medical use.

“We’ve made these proteins that are part of our native immune response,” Putman said. “You can use them to treat an infection.”

To get the bacteria to make the proteins, the team inserted a “biobrick” into the existing genetic code of the bacteria. A biobrick is a standardized piece of DNA code with a known function. Having these standard parts means biological engineers don’t have to create new codes from scratch every time, Putman said.

“It’s taking genetic engineering and synthetic biology and putting it in a much more user-friendly media,” said team member Charles Barentine.

Once the team produced the necessary AMPs, they thought about the spider silk produced at USU.

“We were thinking, ‘That could be used for a medical suture, why don’t we make them antibiotic as well?'” Putman said.

Barentine, also a junior studying biological engineering, said they genetically linked the sequence for spider silk with the sequence for the AMP in hopes of getting a strong antibacterial substance. The material could be used for medical sutures, bandages or even prosthetics, Putman said.

According to Putman, they were able to produce the silk protein with the AMP attached to it, a promising result. But they still have a lot of tests to run before it’s ready.

“We would like to pursue it more because we don’t know if it’s viable yet,” he said.

Barentine said they have to test how the antibacterial properties of the AMP and the material properties of the silk changed after they were linked together.

Another challenge for the team is producing more of the proteins.

“Ideally, we’d like to produce it in a high enough quantity to have a physical product… and then test it,” Putman said.

To produce enough protein, Putman said they need a bioreactor, a growth tank with billions of bacteria in a medium. It takes engineering skills to design and optimize the process.

Putman and Barentine both hope to get into graduate school. Putman is particularly interested in pursuing the medical aspects of biological engineering, which was why he was excited for this year’s project. Barentine said he’s not sure yet what career path he’ll pursue.

“There really are so many options,” Barentine said. “I mean, we can pursue biomedical, things like gene therapy, even straight up engineering.”

The biological engineering program includes microbiology, biochemistry and physics classes, Barentine said. Students are required to take the same courses as mechanical engineers, like statics and fluids.

“We’re qualified to design engineering systems as well as biological systems,” Barentine said.

Some of the big questions biological engineers tackle are making biofuels and curing diseases, including cancer.

“No goal is too big,” Putman said.