Spinning possibilities: USU’s spider silk research

Attendees of a new exhibit in celebration of the National Park Service centennial in August were witnesses to collaborative art and science projects dedicated to exploring “the beauty and wonder of spiders.”

The projects on display at the exhibit, located at the University of Wyoming-National Park Service Research Center, did not include The North Face’s ‘Moon Parka’ — a jacket spun from a protein microfiber modeled after spider silk — as hoped.

“I would’ve loved to have seen it in person,” said Randy Lewis, a professor of biology at Utah State University’s BioInnovations Center who spoke at the event.

Lewis said he thought the coat didn’t show because Spiber — the Japanese company that engineered the artificial silk used in the jacket — “didn’t want to have it out of their direct hands.”

Material for the jacket was inspired by spider silk, which “only scratches the surface of the potential offered by proteins,” according to Spiber’s website. As such, the jacket’s design involved the “skillful combination of the 20 types of amino acids” found in spider silk protein, but not the protein itself.

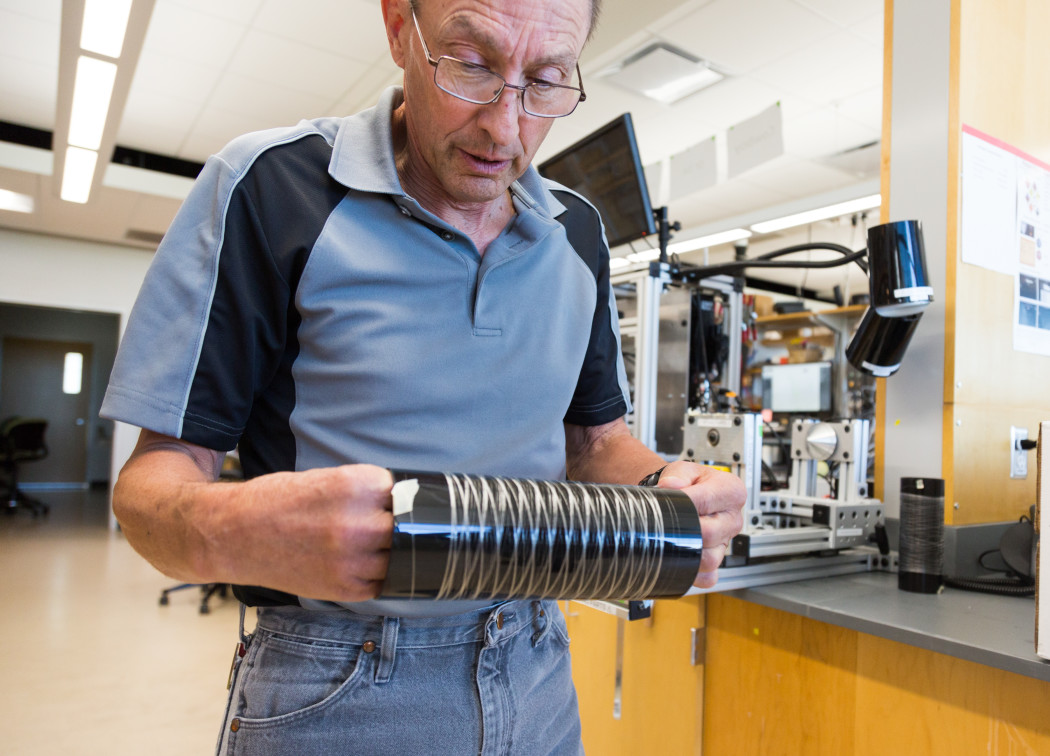

While innovations like the Moon Parka may play an important role in the sustainable development of protein microfibers, researchers at USU’s BioInnovations Center hope to use the spider silk they have researched and produced to make improvements that go beyond the fashion industry.

“The stuff that we make,” said Breton Day, a biology student, “is an exact copy of the DNA of the spider … we produce a smaller protein, but what we have is exactly the same.”

The protein engineered for the Moon Parka was based off of spider silk, but “it’s pretty different,” Day said. For instance, the Moon Parka’s spider silk protein was engineered to be water soluble — the opposite of natural spider silk.

Danielle Gaztambide, an undergraduate studying biological engineering, said one of the major problems with producing artificial spider silk is the protein’s large size, which makes it hard to duplicate.

“That’s one of the trade-offs in this research is you have to get a protein long enough that you can get good properties that compare to natural silk,” Gaztambide said. “The longer the protein, the better the properties.”

“It’s pretty hard to make a protein that big,” Day said, “but as far as we know, ours is the closest.”

While size makes it more difficult to duplicate, it also makes the protein more versatile, which means spider silk can be used for more than clothing.

“We’re not as focused on the marketing of spider silk, we’re focused on what spider silk can do,” Gaztambide said.

Materials made from spider silk protein have the potential to replace carbon fiber and could also prove useful in medical research, since spider silk protein is biocompatible, Lewis said.

“We’ve worked on all kinds of things,” said Gaztambide, “from coatings to gels, adhesives — there’s a lot of potential in the medical field for spider silk.”

Lewis explained that spider silk protein is compatible with the human body and could be used as an adhesive or coating in things like dental implants or catheters.

In addition to being compatible with the human body, Lewis said spider silk “also has a combination of very high strength with flex,” which makes it better than carbon fiber for producing lightweight vehicles and drones.

For now, BioInnovations researchers are working on making the protein easier to produce in large quantities, which might include incorporating spider silk genes into alfalfa plants so farmers could grow spider silk, Gaztambide said.

“In the future we see this as a big product on the market,” Day said. “It’s stronger than steel, tougher than Kevlar. Hopefully it will be cheap enough to make that tons of stuff is made out of it, and it will be cool that we were here at the beginning, helping work on it.”

@alyssarbrts