Taking a look at fireworks

Oooh, Ahhh. Many have watched a firework show on the Fourth of July in awe, but may not think twice about the organization that makes the show a success.

One such manufacturer is located in the rural areas outside Logan city limits. At the head of their quarter-mile long dirt road is a sign notifying people of the danger of explosives on the premises.

Fireworks West is the only fireworks manufacturer in the Western United States, and competes strongly with larger, more famous and more established companies that have been operating in the East for more than a hundred years. They manufacture fireworks for their own shows, including the Fourth of July celebration at Romney Stadium, and their fireworks have been seen in shows like those at Disney World, the Super Bowl and the Calgary Olympics.

“There is almost not a show in the U.S. that doesn’t have some of our product in it,” said the company founder, Ralph Degn.

The company has been operating in Logan since about 1976, when Degn sold displays to various clients in the Intermountain Region who were celebrating the nation’s bicentennial. Most fireworks were imported from China, Japan and Taiwan, in addition to the companies manufacturing in the Eastern United States.

Fireworks West, like all other manufacturers, make fireworks the same way they have been made for centuries. In 1986, Dean Burch, president, devised a new way of manufacturing fireworks that allowed Fireworks West to make more fireworks faster, more consistently and more efficiently. The component process that Burch developed allows the company to put out 800-1000 shells a day, compared to 50-60 previously. Burch’s method of building a firework broke the product into separate components that are put together with the chemicals needed. The components are then glued together with a bonding agent, which reduces the amount of time people are exposed to the explosives, making it a much safer process. Safety is key in this industry. The first two rules in firework manufacturing are to keep quantity low and exposure time to a minimum, said Vice President, Al Burns. Only a certain amount of materials are available in a work space at one time, and completed fireworks are quickly placed in storage.

“Once they go into storage, the exposure time is over with,” Burns said.

All their buildings are wired with completely enclosed lighting and wiring to avoid any possibility of sparks in the work areas.

All equipment is grounded to prevent the buildup of static electricity.

Employees must wear clothes made of cotton that don’t easily buildup static electricity.

Degn said the company employs only 12 employees and works them no more than 40 hours a week. “Our employees are sacred to us,” he said.

“We never anticipate becoming a big company,” Burns said. He said they look for people who will be with the company for a while, who are responsible and care about each other.

The company is a tight-knit organization. Recently if presented before the Olympic Organizing Committee, competing against some of the biggest companies in America. Burns said he was impressed with the way they worked together.

“Everybody was focused. We went down there and we did an A+ job,” Burns said.

Fireworks West has had its product in many high-level events.

Their fireworks have been shot at the Washington Monument and Lincoln Memorial in Washington, D.C., at events in Las Vegas, the Kentucky Derby, the Calgary Stampede and at many NBC- sponsored ski events.

A firework consists of a fuse, which is lighted after the firework has been dropped down into the mortar.

The fuse lights a lift charge, an explosive that shoots the shell into the air.

The lift charges must be measured out to provide a certain weight with a certain amount of lift to ensure that the firework reaches the proper height for explosion.

The lift charge also lights a time fuse that also must be a precise size to ensure that it ignites the chemicals in the canister when the shell reaches its apex.

The chemicals are in a canister, packed around a break charge – another explosive meant to blow the canister apart and light the chemicals to make the colors and designs in the sky.

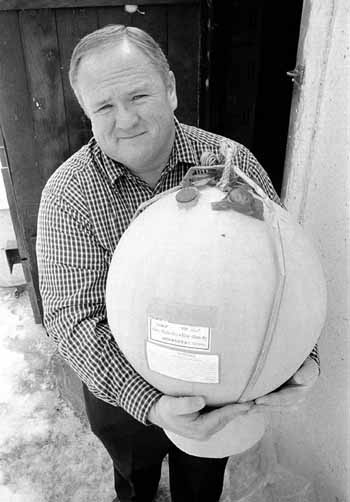

When the canister is glued together and the fuses are put into place a label is put on it, the shell is packaged and put into storage in one of several bunkers on the 5-acre site.

“That’s one of the reasons that we really appreciate working with the local authorities. We have a good system where we can put on a show,” Burns said. Some fireworks companies have to travel 50 to 100 miles to test their product.

Fireworks West not only manufactures fireworks, but it also provides the service of shooting shows for clients within a certain distance. Shooting a show involves setting up all of the fireworks, choreographing the show and procuring insurance for the venue that the display is held in.

“Doing the show is only part of the work, that’s when the work begins,” Burns said.

After the show is over the crew must clean up its equipment, monitor and clean up the fallout area, and clean up the mess created by the fireworks.

The crew also returns early the next morning to continue cleanup and monitoring the fallout area.